Project Blog

with artist SammyJo Miller

The Mountain Lake Public Library’s new sign

Project blog by: Artist SammyJo Miller

April 7, 2025

Hello readers!

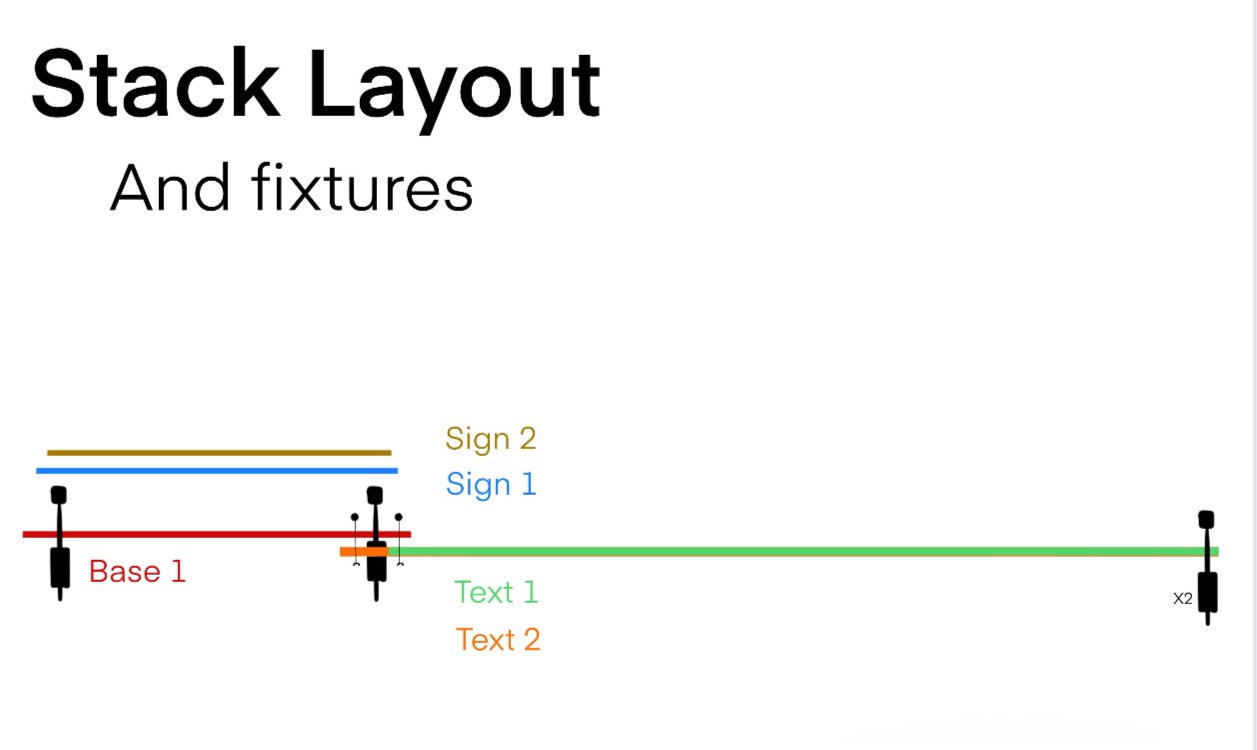

This new project is funded by a private donor for the Mountain Lake public library. Design began earlier this year. I worked directly with Midway Iron and Metal Supply of St. Cloud, MN. The process requires some math and geometry skills. Then the plans are sent to Brian at Midway and he prepares the design for plasma cutting. The images featured are parts of that collaborative effort.

April 9, 2025

Today I made the journey to St. Cloud to pick up the metal from Midway. They were very friendly and helpful, loading all the metal into my vehicle for me. It was a great opportunity to say hi to the people I have been communicating with via email, and touch base about other projects in the works.

Work started as soon as I returned to the studio, it was time to prepare the workshop for the painting process.

April 15, 2025

All 5 metal pieces have been primed with 2 coats. The priming process is not as easy as spray and go, first the metal needs to be throughly cleaned and dried. If you skip this step the paint will crackle when you apply it to the metal. Looks like we are good to go, crackle free and ready for paint

April 20, 2025

The last coat of primer went on the letters today, and the first coat of blue on other sections. I’m so happy that the weather is cooperating. There is a small window of temperature and humidity that is required for ideal spray painting conditions, and we are projected to see a lot of that in the next week!

April 22 - May 1

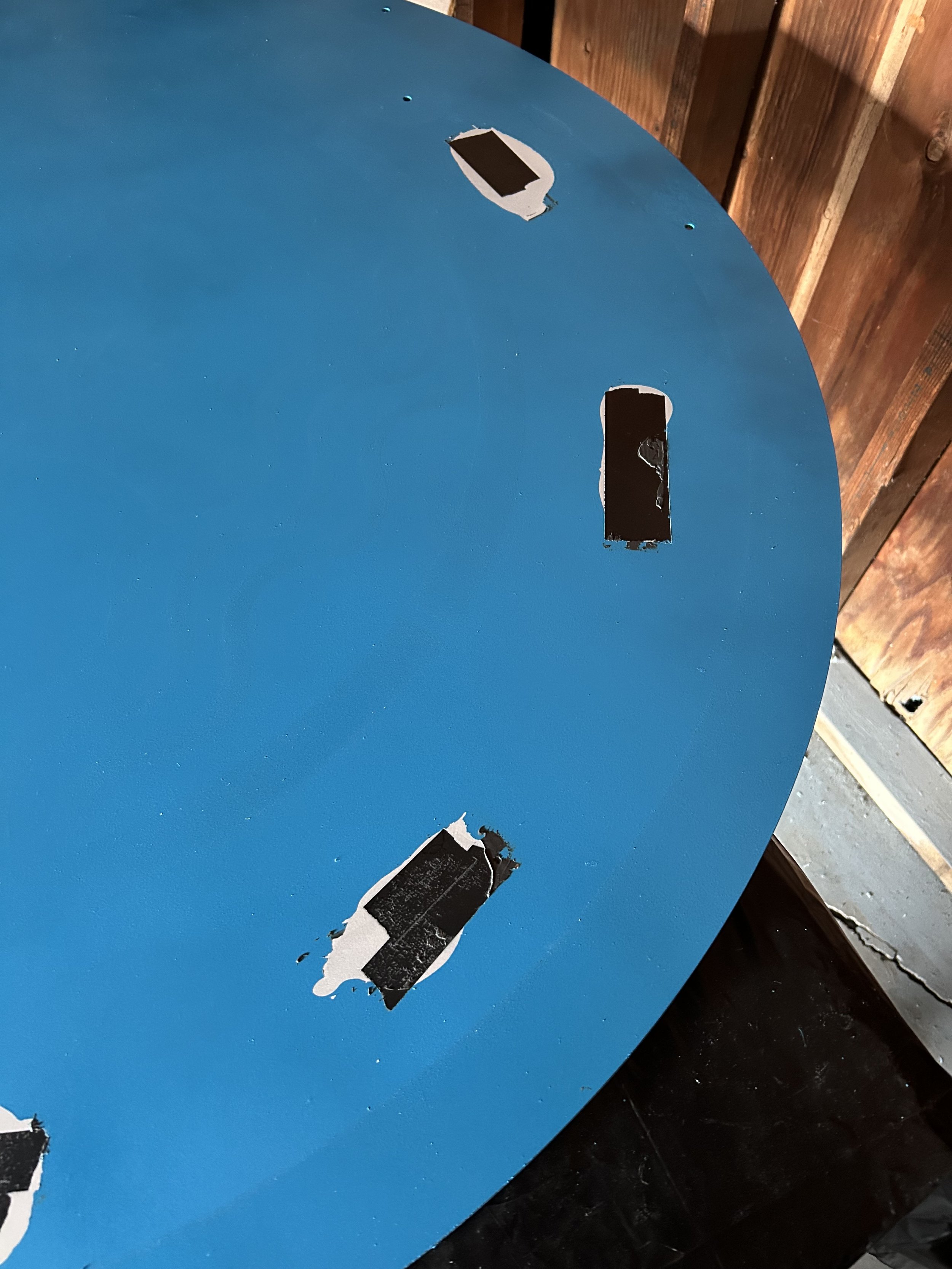

So… spray paint is a finicky medium. I check the temperature and humidity projections every day before I head to the shop to spray. I properly clean the and prep everything before I start, and apply thin even coats…

And this still happened! See photo. Upon doing further research, this is a common problem with spray paint. If a butterfly flaps its wings in New Jersey your spray paint could have a texture issue. So I have spent this time sanding, cleaning, and reapplying spray paint to smooth the texture as much as possible. It is finally returning to an acceptable finish. New images coming with the next update.

May 18th

The weather provided a brief respite from humidity and rain on Sunday and I was able to adhere the logo sections of the sign. The adhesive used was an epoxy, E6000, meant to affix metal surfaces. The stats on this product are impressive! It is my understanding it should be more than capable of holding this type of project in place, but I am keeping the grinding tools and welder on standby. I have a shaky relationship with adhesives!

In order for it to properly adhere the pieces, masking tape was used to keep portions of the surface free of paint during the painting process. This tape was removed and the epoxy was applied to those areas, creating a metal to metal bond.

Once the clouds clear on this rainy week, I will be starting the clear coat on the three large sections and going to pick up hardware!

May 29th

My history with adhesives holds true…

The E6000 popped, yeah that’s the sound it made, it popped as we maneuvered the logo section to seal coat the back. This is frustrating, but I knew this could be a problem, so it is time to proceed with the backup plan.

Plan B will be to add mounting holes through the different layers of the logo sign. This is an acceptable solution because I did have concerns about the current mounting configuration. This plan will add structural support while solving the adhesive issues.

This plan has put the project behind schedule, and requires additional steps after the project has been mounted.

Watch the plan come to fruition in the next few days! Then I’ll apply a poly finish and it is off to Mountain Lake!

June 6th

I am on the final layer of clear coat for the sign!

To solve the problem created by the adhesive, and add structural integrity to the mounted sign, 2 new holes were drilled through it. This is not the route I wanted to go, but it will solve more then one problem. My hesitation was because it creates additional steps in the completion of the project, and adds to the complexity of mounting it. After the sign is hung I will need to revisit the location and spray the bolts so they do not interfere with the aesthetics of the design.

This week the project will be ready to travel! I will meet with the installation specialist and provide mounting instructions.

June 14th

The sign is all wrapped up and ready to make its way to Mountain Lake for installation!

The installation date is June 27th and there is an official unveiling event happening on June 28th, 2PM, at the Mt. Lk. Public Library.

Join us for the unveiling event, or watch the blog for pictures of the fully installed sign to come next week!

June 27th

This past Friday marked the installation of the new sign for the Mountain Lake Public Library. Created to complement the library’s historic character while offering a fresh, welcoming presence, the sign now stands proudly near the entrance, a new beacon for one of Mountain Lake’s most vital public spaces.

The installation was handled by a talented local mason and his team, who did a beautiful job setting the piece in place. Their care and craftsmanship made the process smooth, and I’m grateful for their collaboration. There’s still a bit of finishing work ahead, I’ll be returning to add final painted details soon, likely during my next trip down to install the new sculpture project nearby.

This sign has been a long time coming, and I’m thrilled to see it in its new home. Projects like this, where public art, functional design, and community pride intersect, remind me of the quiet power of small-town spaces. I hope this new sign invites people in, sparks curiosity, and helps celebrate all the good that happens inside the library’s walls.

Stay tuned for an update once the final painted touches are complete, and for more on the sculpture project coming soon to Mountain Lake!

A Sign to Celebrate: Final Touches & Unveiling at Mountain Lake

This week marked the true completion of the Mountain Lake Public Library sign project, and what a perfect way to finish: with final paint touchups and a public unveiling, held in conjunction with the installation of my newest sculpture just across the way.

After the sign was mounted earlier this summer by a skilled local mason and his team, I returned to Mountain Lake to add a few final painted details and weather-sealing. With the piece fully finished, the library now has a warm, handcrafted welcome that reflects its central role in this vibrant community.

To celebrate, we gathered with community members, library staff, and guests for a modest unveiling event. It was a joy to see the sign in use and in context, bringing together books, art, and shared space in the most genuine way. The event also highlighted the library’s newest public art addition, a sculpture that now shares the lawn with the sign, marking an evolving and creative corner of town.

Thank you to everyone who made this project possible—from the team at the library, to the local craftsmen, and all the neighbors who stopped by to share kind words. I’m proud to have played a part in helping shape this space, and I hope the new work welcomes readers, visitors, and dreamers for many years to come.